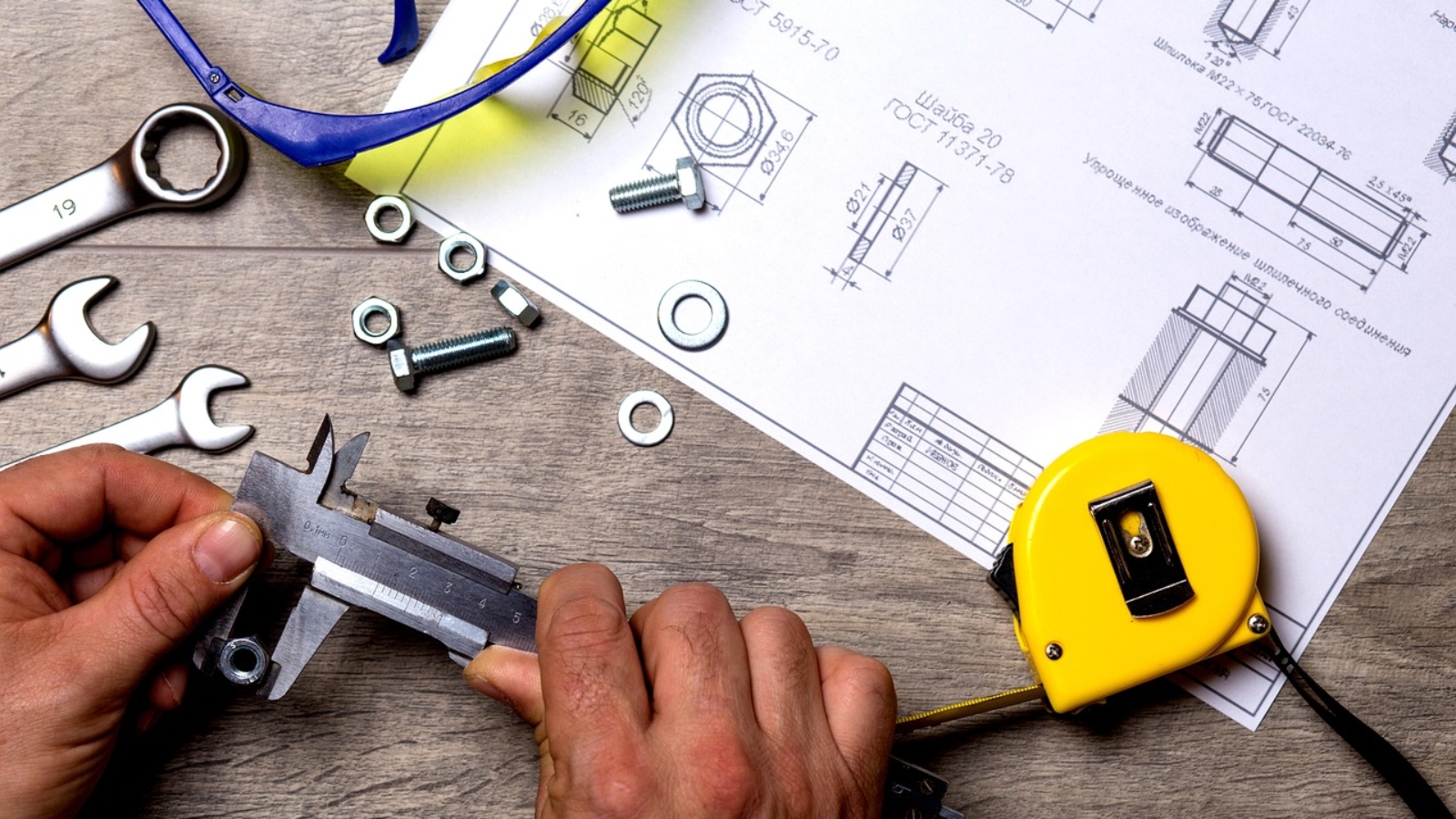

Regular maintenance is an essential aspect of any industry, and the construction sector is no exception. In the world of construction, the safety of workers and the success of projects depend on the reliability and efficiency of tools and equipment. Regular maintenance of construction tools and equipment can prevent costly downtime, delays, and accidents. Proper maintenance ensures that the tools and equipment are in good working condition, extending their lifespan and helping avoid unnecessary expenses. However, many construction companies overlook the importance of regular maintenance, leading to significant losses and safety hazards. In this blog post, we will discuss the importance of regular maintenance for construction tools and equipment, its benefits, and how to incorporate it into your construction business.

Why is Regular Maintenance Important for Your Construction Tools and Equipment?

Regular maintenance is essential for the longevity of your tools and equipment. Construction tools and equipment are often exposed to harsh environments and conditions, including dirt, dust, extreme temperatures, and heavy use. Without regular maintenance, your tools and equipment will start to wear out, become less efficient, and eventually break down. This can lead to costly repairs, downtime, and lost productivity.

Regular maintenance also helps to ensure the safety of your workers. Malfunctioning or poorly maintained tools and equipment can cause accidents and injuries on the job site. Regular maintenance can help to identify potential safety issues before they become major problems, and prevent accidents and injuries from occurring.

Tips for Maintaining Your Construction Tools and Equipment

Now that we’ve established why regular maintenance is so important, let’s take a look at some tips for maintaining your construction tools and equipment.

- Follow the manufacturer’s instructions: The manufacturer’s instructions are the best source of information for maintaining your tools and equipment. Make sure to read the manual and follow the recommended maintenance schedule.

- Keep your tools and equipment clean: Dirt, dust, and debris can build up on your tools and equipment, causing them to malfunction or break down. Regular cleaning can help to prevent this from happening.

- Inspect your tools and equipment regularly: Regular inspections can help to identify potential problems before they become major issues. Look for signs of wear and tear, damage, or loose parts.

- Replace worn or damaged parts: If you notice any worn or damaged parts during your inspections, make sure to replace them promptly. Continuing to use worn or damaged parts can cause further damage to your tools and equipment, and potentially cause accidents or injuries.

- Store your tools and equipment properly: Proper storage can help to prevent damage and prolong the life of your tools and equipment. Make sure to store them in a dry, cool place, and protect them from dust and debris.

By following these tips and maintaining your construction tools and equipment regularly, you can ensure that they stay in top condition, and avoid costly repairs, downtime, and lost productivity. Regular maintenance also helps to ensure the safety of your workers, and prevent accidents and injuries on the job site.

Conclusion

Regular maintenance is essential for the longevity of your construction tools and equipment. By following the manufacturer’s instructions, keeping your tools and equipment clean, inspecting them regularly, replacing worn or damaged parts, and storing them properly, you can ensure that your tools and equipment stay in top condition, and avoid costly repairs and lost productivity. Regular maintenance also helps to ensure the safety of your workers, and prevent accidents and injuries on the job site.